OIL & GAS

COMPUTATIONAL FLUID DYNAMICS (CFD)

What is Computational Fluid Dynamics?

Computational Fluid Dynamics (CFD) deals with the analytical solutions of differential equations governing momentum, mass transport and kinetic energy. CFD is primarily based on approximating the Navier-Stokes equations developed by Claude-Louis Navier and George Gabriel Stokes over 200 years ago. The capacity to approximate the Navier-Stokes equations was never realized until many years later during the 1960s after the advent of the computer. Over the years computing power has increased to allow for more complex and accurate approximations of the Navier-Stokes equations. CFD has now become a key instrument for analysis in many industries.

Where is it used?

With the advancement of computer technology and processing power, CFD has become the tool of choice for many types of analysis. CFD is used to save cost and analyze flow regimes in bodies with complicated geometries and physical properties. Special problems such as modeling crude oil as it flows through a three phase separator can be effectively optimized with CFD for performance and cost savings.

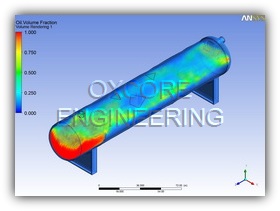

The illustration (Figure 1) shows a CFD Analysis for a horizontal separator used for crude oil. Under normal operation the separator splits the crude oil into its 3 phases (oil, water & gas) while maintaining a certain level of water at the bottom. The water at the bottom of the vessel helps prevent gas from leaving through the water and oil outlets. CFD Analysis can help determine what happens when an upstream slug of gas hits the separator. Predictions can be made that help determine the mixture interface levels and where the interfaces need to be located to withstand given amounts of upstream gas slugging.

In 2016, Oxcore Engineering became the first company to successfully develop a CFD model for a complete downhole system of tubes and nozzles. Erosion rates were determined inside the tubes and at each nozzle location. Sand concentration was calculated at each nozzle and the overall sand distribution was calculated for various slurry flow rates.

Below is a list of services provided by Oxcore where CFD is useful:

• Multiphase Analysis and Optimization

• Equipment and Vessel Optimization

• Erosion Studies

• Joule-Thompson Cooling Analysis

• Hydrodynamic Analysis

• Hydrodynamic Optimization

• Phase Change in Oil and Gas Pipelines

• 3 Phase Flow - Pipeline Regimes

• Pipeline Slugging Analysis

• Distillation Column Analysis

• Flare Header Analysis

• Chemical Dispersion Studies

OIL & GAS

COMPUTATIONAL FLUID DYNAMICS (CFD)

What is Computational Fluid Dynamics?

Computational Fluid Dynamics (CFD) deals with the analytical solutions of differential equations governing momentum, mass transport and kinetic energy. CFD is primarily based on approximating the Navier-Stokes equations developed by Claude-Louis Navier and George Gabriel Stokes over 200 years ago. The capacity to approximate the Navier-Stokes equations was never realized until many years later during the 1960s after the advent of the computer. Over the years computing power has increased to allow for more complex and accurate approximations of the Navier-Stokes equations. CFD has now become a key instrument for analysis in many industries.

Where is it used?

With the advancement of computer technology and processing power, CFD has become the tool of choice for many types of analysis. CFD is used to save cost and analyze flow regimes in bodies with complicated geometries and physical properties. Special problems such as modeling crude oil as it flows through a three phase separator can be effectively optimized with CFD for performance and cost savings.

The illustration on the right shows a CFD Analysis for a horizontal separator used for crude oil. Under normal operation the separator splits the crude oil into its 3 phases (oil, water & gas) while maintaining a certain level of water at the bottom. The water at the bottom of the vessel helps prevent gas from leaving through the water and oil outlets. CFD Analysis can help determine what happens when an upstream slug of gas hits the separator. Predictions can be made that help determine the mixture interface levels and where the interfaces need to be located to withstand given amounts of upstream gas slugging.

Below is a list of services provided by Oxcore where CFD is useful:

• Multiphase Analysis and Optimization

• Distillation Tray Column Analysis

• Equipment and Vessel Optimization

• Joule-Thompson Cooling Analysis

• Hydrodynamic Analysis and Optimization

• Phase Change in Oil & Gas Pipelines

• 3 Phase Flow - Pipeline Regimes

• Pipeline Slugging Analysis

• 3 Phase Separator Analysis

• Flare Header Analysis

• Chemical Dispersion Studies

FIGURE 1

--CLICK TO ENLARGE--

3 Phase Separator - Oil Phase